When it comes to managing a warehouse in Sydney, one of the most critical yet often overlooked elements is the condition and quality of the flooring. Warehouse floors must endure heavy machinery, constant foot and vehicle traffic, chemical spills, and wear-and-tear-all — while maintaining safety and efficiency. That’s why epoxy floor coating has become the go-to solution for many Sydney warehouse owners looking for a durable, attractive, and low-maintenance flooring option.

If you’re considering an epoxy floor coating service for your warehouse, it’s essential to understand what the process entails, the benefits, and what you should expect from professional contractors. This guide will walk you through everything you need to know to make an informed decision and get the best results.

What Is Epoxy Flooring and Why Is It Ideal for Warehouses?

Warehouse Epoxy flooring is a durable surface coating created by combining resin and hardeners, which chemically react to form a tough, rigid plastic layer. This material bonds tightly to concrete floors, creating a seamless, durable, and resistant surface that withstands heavy impacts, abrasions, and chemical exposure.

For warehouses, epoxy flooring offers several advantages:

- Durability: Epoxy coatings strengthen concrete floors and help prevent cracks, chips, and wear.

- Chemical Resistance: Ideal for warehouses dealing with oils, solvents, and other industrial chemicals.

- Safety: Epoxy coatings can be customized with slip-resistant additives to help minimize workplace accidents.

- Low Maintenance: Epoxy floors are easy to clean and maintain, saving time and costs.

- Aesthetic Appeal: Offers a professional, clean look that can be customized with colors and finishes.

What to Expect from a Professional Warehouse Epoxy Flooring Service in Sydney

A professional epoxy flooring service is not just about applying a coat of paint. It involves a detailed process that ensures your warehouse floor will be safe, durable, and visually appealing for years to come. Here’s what you should expect:

1. Initial Assessment and Consultation

Before any work begins, a reputable Sydney epoxy flooring company will inspect your warehouse floor to evaluate its current condition. This includes checking for cracks, moisture levels, surface contamination, and overall wear. The assessment helps determine whether repairs or surface preparation are needed.

You’ll also discuss your specific requirements:

- What kind of traffic and machinery will the floor endure?

- Are there any chemical spills or exposure risks?

- What level of finish and aesthetics do you prefer?

This initial consultation is crucial for planning the right epoxy system tailored to your warehouse needs.

2. Surface Preparation

One of the most critical steps for a long-lasting epoxy floor is proper surface preparation. Professionals will:

- Clean the floor thoroughly to remove grease, oil, dirt, and old coatings.

- Grind or shot-blast the concrete to create a rough texture for better epoxy adhesion.

- Fill any cracks or holes using appropriate fillers or concrete patching compounds.

- Test the floor for moisture — excess moisture can prevent epoxy from curing properly.

Skipping or rushing this step can result in issues like peeling, bubbling, or early surface deterioration.

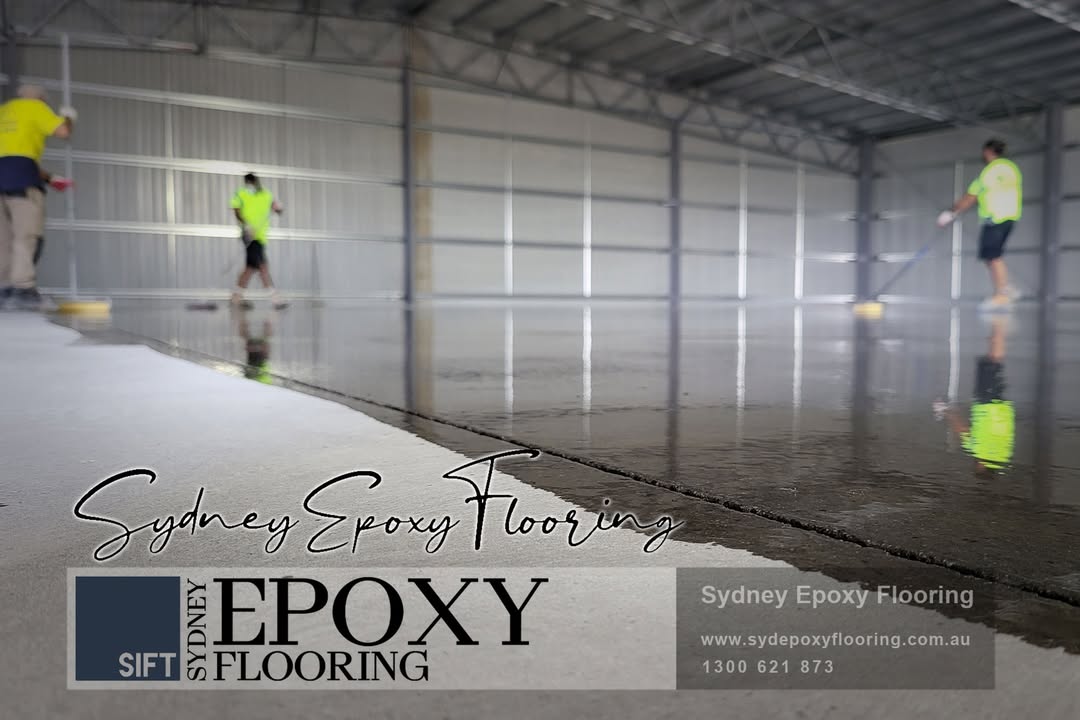

3. Applying the Epoxy Coating

Once the surface is prepped, the epoxy is applied in multiple layers:

- Primer coat: Seals the surface and improves bonding.

- Base epoxy layer: Provides thickness and strength.

- Additional coats or topcoat: Adds durability and may include UV protection or anti-slip additives.

The application must be done under controlled conditions to allow proper curing. Professionals use specialized tools like rollers, squeegees, and trowels to ensure even coverage.

4. Curing Time and Inspection

Epoxy coatings typically require 24 to 72 hours to cure fully, depending on the type used and environmental conditions. During this period, access to the warehouse floor will be limited.

After curing, the contractor will inspect the floor to ensure the coating is uniform, free of defects, and meets quality standards.

5. Final Walkthrough and Maintenance Tips

The service doesn’t end with installation. A professional company will walk you through proper maintenance procedures to extend your floor’s life, such as:

- Cleaning guidelines

- Recommended cleaning agents

- Periodic inspections and touch-ups

Good maintenance helps retain your epoxy floor’s appearance and functionality for many years.

Why Choose a Local Sydney Epoxy Flooring Expert?

Sydney warehouses face unique challenges, including varying climate conditions and industrial requirements. Choosing a local professional ensures:

- Expertise in local regulations and standards

- Quick response times for inspections and repairs

- Knowledge of Sydney’s specific warehouse environments

- Access to trusted suppliers and quality epoxy products

At Sydepoxyflooring.com.au, we specialize in warehouse epoxy flooring solutions tailored to Sydney businesses, combining years of experience with quality workmanship.

Key Benefits of Epoxy Flooring for Your Sydney Warehouse

- Enhanced Safety

Epoxy coatings can incorporate anti-slip additives to reduce the risk of accidents caused by slips and falls. - Cost-Effective Longevity

Protect your concrete floor from expensive damage and reduce maintenance costs over time. - Improved Cleanliness

Epoxy’s seamless and non-porous surface resists dust and dirt buildup, promoting a cleaner, more hygienic environment. - Boosted Productivity

A durable and visually appealing floor creates a safer and more pleasant workspace, improving employee morale and efficiency. - Customizable Appearance

Choose from a variety of colors, textures, and finishes that reflect your brand or improve warehouse lighting.

Frequently Asked Questions

What is the lifespan of epoxy flooring in a warehouse environment?

With proper installation and maintenance, epoxy floors can last 10+ years even under heavy industrial use.

Is epoxy flooring strong enough to withstand forklift and heavy machinery traffic?

Yes, industrial-grade epoxy coatings are designed to withstand the weight and abrasion from forklifts and machinery.

Is epoxy flooring resistant to chemical spills?

Most epoxy coatings provide excellent chemical resistance, protecting your floor from oils, solvents, and cleaning agents.

How long does the installation process take?

Installation and curing usually take 3 to 5 days, depending on the size of the warehouse and the condition of the floor.

Can I apply epoxy flooring myself?

DIY kits are available, but professional installation ensures correct surface preparation, optimal adhesion, and long-term durability.

Ready to Upgrade Your Warehouse Flooring?

If you own or manage a warehouse in Sydney, investing in professional epoxy floor coating is a smart decision that pays off with enhanced safety, durability, and appearance. Don’t compromise on quality — choose an expert service that understands your needs and delivers reliable results.

At Sydepoxyflooring.com.au, we specialize in warehouse epoxy flooring solutions tailored for Sydney businesses. Contact us today for a free consultation and let us help you protect and upgrade your warehouse floor for years to come.

Get in Touch with the Professional

Have questions or ready to schedule your warehouse epoxy flooring service? Our friendly and experienced team at Sydepoxyflooring.com.au is here to help!

Phone: 1300 621 873

Email: info@sydepoxyflooring.com.au

Address: Unit 123/7 Hoyle Ave, Castle Hill, NSW 2154, Australia

Website: sydepoxyflooring.com.au