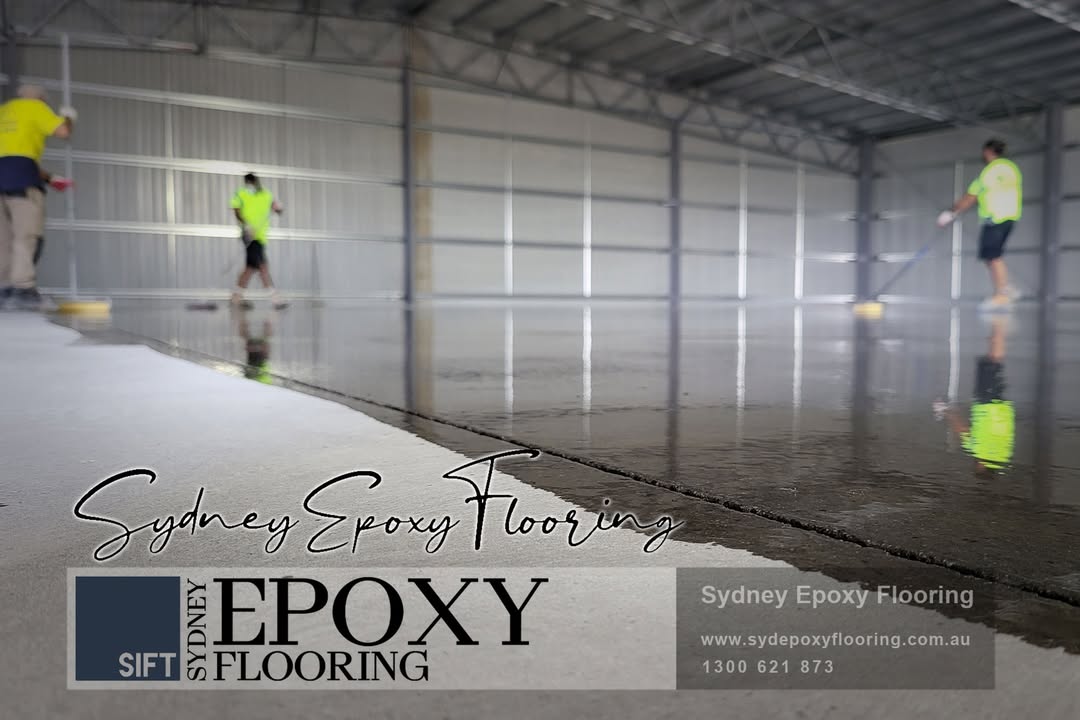

When it comes to beverage manufacturing, safety, hygiene, and durability are non-negotiable. At Syde Epoxy Flooring, we specialize in delivering seamless flooring solutions for beverage facilities in Sydney, built to withstand constant moisture, chemical exposure, and strict hygiene standards.

Why Seamless Flooring is Crucial for the Beverage Industry

In the beverage industry, floors are exposed to frequent spills, high humidity, and sugary liquids that can quickly lead to bacterial growth, contamination, and safety hazards. Our seamless epoxy flooring provides a non-porous, chemical-resistant, and easy-to-clean solution that not only enhances your facility’s safety but also helps you maintain compliance with health and safety regulations.

Key Benefits of Our Beverage Flooring Systems

- Chemical Resistance

Our floors are engineered to resist aggressive substances like acids, sugars, and cleaning agents. This means no surface breakdown, peeling, or erosion, even under harsh conditions. - Moisture & Contamination Control

The non-porous surface ensures liquids cannot seep into the substrate. This drastically lowers the risk of contamination and bacterial growth—an essential feature in beverage production environments. - Easy Maintenance

Thanks to its seamless design, our flooring is incredibly easy to sanitize. There are no joints or cracks where bacteria or grime can accumulate, making routine cleaning fast and efficient. - Slip Resistance for Worker Safety

Slippery floors are a major safety concern in beverage processing areas. We can tailor the flooring finish to include anti-slip textures, reducing the risk of workplace accidents.

Customised Flooring Solutions for Your Facility

Whether you run a brewery, juice manufacturing plant, bottling facility, or soft drink production line, our team provides tailored flooring systems that meet the unique requirements of your space. We assess your operational needs and recommend a solution that ensures long-term durability, hygiene, and workplace safety.

Why Choose Syde Epoxy Flooring?

As one of Sydney’s most trusted epoxy flooring providers, we bring years of industry experience, premium-grade materials, and a customer-first approach. We’ve worked with numerous food and beverage clients to deliver seamless, safe, and hygienic flooring that stands the test of time.

Frequently Asked Questions (FAQ)

1. Why is seamless flooring important for beverage facilities?

Seamless flooring prevents contamination, supports hygiene, and reduces slip hazards in wet and high-moisture environments.

2. Is your flooring resistant to sugar and acidic liquids?

Yes, our chemical-resistant flooring handles exposure to sugars, acids, and cleaning agents without damage.

3. How easy is it to clean seamless epoxy flooring?

Very easy. The non-porous, joint-free surface makes cleaning quick and prevents bacteria buildup.

4. Can your flooring reduce slip risks in wet areas?

Absolutely. We offer anti-slip finishes that improve safety in high-spill zones common in beverage facilities.

5. Do you provide custom flooring solutions for different beverage operations?

Yes, we tailor flooring systems to fit breweries, juice plants, bottling lines, and more.

Ready to upgrade your beverage facility with industry-leading seamless flooring?

Contact Syde Epoxy Flooring today for a free consultation and quote.

📞 Phone: 1300 621 873

Unit 123/7 Hoyle Ave,

Castle Hill, NSW 2154,

Australia