After years of working inside factories, warehouses, and production sites across Sydney, I’ve learned one thing very quickly: heavy machinery exposes flooring weaknesses faster than anything else. Forklifts, reach trucks, fixed plant equipment, pallet systems, and constant washdowns all push floors to their limit.

That’s why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas is not just a marketing question. It’s a real operational concern for local businesses trying to reduce downtime, improve safety, and avoid constant repairs.

From Western Sydney logistics hubs to Inner West manufacturing facilities, many sites start with standard concrete. Within a few years, cracks, dust, stains, and hygiene issues appear. This guide explains why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas, based on real site conditions, not theory.

Why Heavy Machinery Is So Hard on Industrial Floors

Industrial machinery places stress on floors in ways most people underestimate. Weight is only one factor. Vibration, turning forces, braking, and repeated impact all contribute to long-term damage.

In Sydney, these issues are magnified by:

- Long operating hours

- Older industrial slabs are not designed for modern loads

- Moisture and humidity in coastal areas

- Dust and grit in Western Sydney facilities

Understanding Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas starts with recognising that untreated concrete is rarely enough.

Problem 1: Frequent Cleaning and Repairs Disrupt Operations

The problem

One of the biggest complaints we hear from industrial operators is how often floors need cleaning, patching, or temporary repairs. Heavy machinery accelerates wear, especially in traffic lanes and loading zones.

In many Sydney facilities, this leads to:

- Regular crack filling

- Ongoing patch repairs

- Shutdowns for maintenance

- Increased labour costs

These interruptions affect productivity and safety.

How epoxy flooring solves it

Heavy-duty epoxy flooring in Sydney creates a hard-wearing surface designed to handle repeated machinery movement. Once installed correctly, the need for frequent floor repairs drops significantly.

This is a key reason Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas again and again.

Problem 2: Dust and Debris from Untreated Concrete

The problem

Warehouse flooring issues in Sydney often start with concrete dusting. As machinery moves across bare slabs, the surface breaks down and releases fine particles.

This dust:

- Settles on products

- Affects machinery performance

- Creates slip risks

- Increases cleaning time

In regulated industries, dust becomes a compliance concern.

How epoxy flooring solves it

Industrial epoxy floor coating seals the concrete completely. Once cured, there is no exposed cement surface to break down.

For epoxy flooring for industrial facilities in Sydney, dust control is one of the most immediate and noticeable improvements.

This is another practical reason Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas.

Problem 3: Porous Floors Absorb Spills and Contaminants

The problem

Concrete is highly porous. Oils, chemicals, coolants, cleaning agents, and even water soak into untreated floors.

Across Sydney industrial sites, this leads to:

- Permanent staining

- Odours

- Bacterial growth

- Chemical degradation of the slab

Concrete floor damage in industrial buildings often starts with repeated small spills.

How epoxy flooring solves it

Epoxy flooring solutions for factories in Sydney create a non-porous surface. Liquids stay on top, making spills easy to clean and preventing contamination.

This is especially important in food production, manufacturing, and automotive environments.

Problem 4: Hygiene Is Hard to Maintain Around Machinery

The problem

Heavy machinery creates tight spaces, joints, and hard-to-clean areas. When floors crack or wear, dirt and bacteria build up around equipment bases.

For many Sydney facilities, maintaining hygiene becomes labour-intensive and inconsistent.

How epoxy flooring solves it

Epoxy flooring is seamless. There are no grout lines or joints for contaminants to hide in. Floors can be cleaned efficiently, even around machinery.

This is a major reason Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas in hygiene-sensitive industries.

Problem 5: Safety Risks in High-Traffic Machinery Zones

The problem

Machinery areas are high-risk zones. Smooth concrete becomes slippery when dusty or wet. Oil leaks and washdowns increase the risk further.

Slip incidents are a common safety issue in Sydney industrial facilities.

How epoxy flooring solves it

Epoxy flooring for high-traffic areas in Sydney can include anti-slip aggregates tailored to the site. This improves traction without compromising cleanability.

Safety performance is a core factor in Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas.

Problem 6: Traditional Flooring Systems Fail Under Machinery

The problem

Tiles crack under load. Vinyl lifts under vibration. Painted floors wear through quickly. These systems are not designed for industrial machinery.

Sydney factories often replace these floors far sooner than expected.

How epoxy flooring solves it

Industrial epoxy flooring is engineered specifically for heavy loads and constant use. It bonds to the slab and moves with it, rather than separating or lifting.

This durability explains Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas over traditional options.

How Epoxy Flooring Performs Under Heavy Machinery

| Performance Factor | Untreated Concrete | Traditional Coatings | Epoxy Flooring |

| Load Resistance | Low | Low–Medium | High |

| Dust Control | Poor | Poor | Excellent |

| Chemical Resistance | Poor | Low | High |

| Hygiene | Poor | Medium | Excellent |

| Maintenance Needs | High | High | Low |

This comparison highlights why industrial epoxy floor coating in Sydney is trusted in machinery-heavy environments.

Key Benefits for Machinery-Heavy Industrial Sites

When reviewing Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas, several benefits consistently stand out:

- Reduced downtime for repairs

- Longer floor lifespan

- Improved safety outcomes

- Easier cleaning around machinery

- Better protection of the concrete slab

- Professional appearance for audits and inspections

These benefits directly support operational efficiency.

Why Sydney Conditions Make Epoxy Even More Relevant

Sydney’s industrial zones are diverse. Western Sydney facilities often deal with dust and high forklift traffic. Coastal sites manage humidity and moisture. Inner-city facilities operate with limited downtime.

Epoxy flooring for industrial facilities in Sydney can be tailored to suit these conditions. That flexibility is a major reason it is so widely adopted.

Understanding Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas requires local knowledge, not generic advice.

A Natural Introduction to Sydney Epoxy Flooring

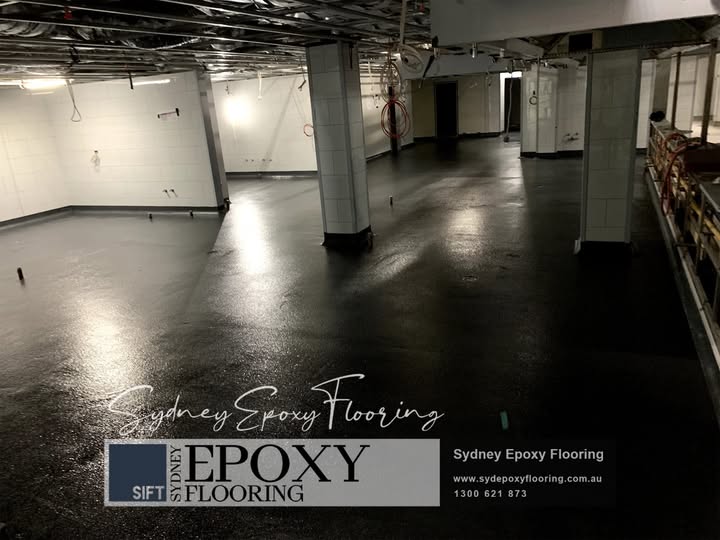

At Sydney Epoxy Flooring, we’ve installed epoxy systems in machinery-heavy environments across Sydney. From logistics warehouses to manufacturing plants, we understand how floors behave under real operational stress.

Our focus is on proper preparation, correct system selection, and long-term performance. Each site is assessed individually to ensure the flooring matches machinery loads and usage patterns.

This local experience underpins Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas.

Experience, Standards, and Best Practice

Industrial flooring around heavy machinery must meet safety and performance requirements. That includes:

- Load-bearing capability

- Slip resistance

- Chemical resistance

- Compliance with Australian standards

Our team works within established guidelines and proven installation methods. Client feedback often highlights durability, reliability, and reduced maintenance.

Local Examples and Use Cases

We commonly see epoxy flooring specified in:

- Western Sydney distribution centres

- Manufacturing plants in the Inner West

- Automotive workshops across Sydney

- Food and beverage facilities

- Industrial workshops and service bays

In each case, heavy machinery is the deciding factor.

Frequently Asked Questions

Is epoxy flooring strong enough for forklifts and machinery?

Yes. Heavy-duty epoxy systems are designed to handle forklifts, pallet trucks, and fixed machinery when installed correctly.

Does epoxy flooring reduce cleaning time?

Yes. Seamless, non-porous surfaces are faster to clean and easier to maintain.

Can epoxy flooring be installed around existing machinery?

Often, yes. Installation can be staged to minimise disruption.

Is epoxy flooring suitable for hygiene-sensitive facilities?

Yes. It is widely used in food production and clean manufacturing environments.

How long does epoxy flooring last in machinery areas?

With proper installation and maintenance, epoxy flooring can perform for many years under heavy use.

When you look closely at Why Industrial Facilities in Sydney Choose Epoxy Flooring for Heavy Machinery Areas, the reasons are practical, not theoretical. Heavy machinery demands strength, safety, and reliability.

Traditional floors struggle under that pressure. Epoxy flooring is designed for it.

For Sydney industrial facilities aiming to reduce repairs, improve hygiene, and protect their concrete slabs, epoxy flooring remains one of the most effective long-term solutions available.

Phone: 1300 621 873

Email: info@sydepoxyflooring.com.au

Address: Unit 123/7 Hoyle Ave, Castle Hill, NSW 2154